Get Rid of Bad Breath

Bad breath, though not common in daily life, has been classified as a medical condition by the WHO. Whether upon

Istar is a specialized digital dental laboratory, and our experienced digital team has excellent digital design capabilities to ensure that crowns and dentures are made to your patients’ satisfaction.

Since 2015, Istar Dental Laboratory has moved into the digital realm of dentistry. By now, we have fully mastered CAD/CAM systems and 3D printing technology, and have made breakthroughs in the way we fabricate teeth using mouth-scan data.

We have combined our experience to come up with a design and fabrication method that is unique to Istar Dental Laboratory, which allows us to achieve a success rate of nearly 100% for your data case, which has stood as a leader in the entire industry!

Whether it’s crowns and bridges, veneers, inlays, removable dentures or dental implants, we can improve the efficiency of your practice and increase patient satisfaction with our approach. Come revolutionize your dental practice with cutting-edge digital solutions!

More and more of Istar Digital Dental Laboratory’s dentist clients are choosing to send digital cases instead of the traditional method of taking impressions because it saves time and improves the accuracy of the dental cases.

Istar scan digital dental lab will provide you with a full range of services, from designing scan data models, crowns, etc., to 3D printing, to cutting and fabrication, and finalizing shipment. All you need to do is to send us the scan data case and Istar will do the rest!

After receiving your scan digital case, we will pass it to our professional dental digital designers. They will analyze the patient’s oral scan data provided by you, checking the occlusal space, scanning the edges of the digital model, etc., to determine whether it meets the fabrication requirements. If it meets the fabrication requirements, they will start designing the crown and model using CAD software.

Once the designers at Istar digital dental laboratory have modeled the scan data, they can print it out using a dental 3D printer. This way is much more accurate than the traditional plaster inverted mold, and likewise, the rework rate of your case will be lower. This is because with traditional plaster models, it is almost inevitable to accidentally scratch or chip the plaster during crown design, which can sometimes result in poorly fitting restorations.

After the crowns have been designed by our designers in the digital dental solutions lab, they are transferred to our production facilities via a CAM system. In the case of PFM crowns, we send them to the Laser Dental 3D Printer for printing and casting; in the case of zirconia crowns, we use a Dental Milling Machine to start cutting. In fact, from this step onwards, the production process for subsequent scan data cases is the same as for normal cases.

Istar digital dental lab is equipped with a variety of excellent equipment that allows us to design and produce your digital case more easily and perfectly.

The 3D printer prints out the completed dental model designed by the dental digital designer in resin material, which completely reproduces the actual condition of your patient's mouth and prepares us for the next step of creating a suitable crown.

The resin models just printed out by 3D printers are somewhat soft, and a special light curing machine is needed to cure these models so that dental technicians can better use them to make crowns and bridges, etc.

Once the PFM tooth has been designed, the data is transferred from the CAM system to the Laser Dental 3D Printer, which prints out the PFM's metal coping.

Dental milling machine is a dental equipment used for cutting zirconium blocks. After the designer has designed the crowns and bridges based on the oral scan data you have transmitted, the machine is used to cut and fabricate them.

Istar can also work with intraoral scan data you provide to create dentures. Compared to fixed dental prosthetics, the process of designing and manufacturing removable dentures using intraoral scan data is actually simpler. This is because they do not require crown design—only the dental model needs to be designed and printed.

If you want to restore your patient’s original crowns or dentures, using an intraoral scanner to capture their oral condition and then sending the scan data to us for design and restoration will be a great idea!

Our designers will use the CAD system to analyze and design based on the scan data, propose solutions, and have our technicians complete the fabrication. This approach is not only faster but also more accurate!

The advent of intraoral scan data has brought tremendous benefits to dental implants. Traditional impression methods can sometimes result in inaccuracies due to various factors, which may affect the precision of crowns and bridges fabricated by dental labs.

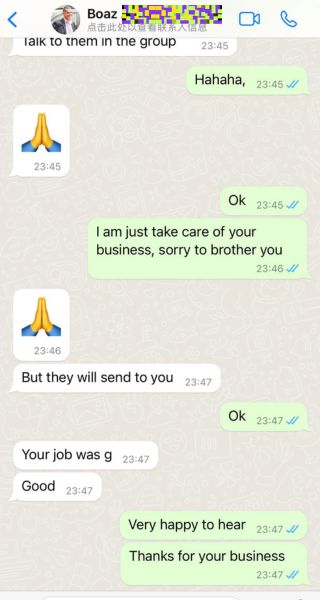

Now that the intraoral scan data is sent to Istar for the fabrication of dental implants, you can communicate with our technicians at any time in case, which will greatly increase the accuracy of the dental implants.

Istar has been focusing on learning and training relevant technical talents since the transition to digital dental solutions lab. By now, we have developed our own set of design and production methods, which are able to quickly and accurately complete the design and production of the intraoral scan data case you send us!

The designers working with intraoral scan data can be considered the core of a digital dental lab, as their work directly impacts the accuracy and aesthetics of cases. The designers at Istar Digital Dental Lab have 7-8 years of design experience. They can quickly and accurately create dental models and crowns based on the scan data you provide, helping you achieve higher patient satisfaction.

Choosing Istar Digital Dental Lab to create crowns and dentures for your patients will save you a lot of time! Once we receive your intraoral scan data case, we will immediately begin designing and manufacturing. A standard case typically takes about 2-3 days, and with shipping time included, we can deliver the case to your clinic within 5-7 days. This is significantly faster than the production time of your local dental labs!

Istar Digital Dental Laboratory, through its expertise and research and development, has continuously reduced production costs without compromising product quality. As a result, we can offer you more competitive prices compared to your local dental labs. This will help you save significantly on expenses in this area, giving you more funds to promote your clinic!

Istar Digital Dental Laboratory has dental and lab partners in more than 30 countries worldwide. Our customer service team has extensive experience to provide you with comprehensive support. So feel confident in sending your intraoral scan data to us—we have the capability to quickly deliver your case to your clinic, no matter which country you are in!

Bad breath, though not common in daily life, has been classified as a medical condition by the WHO. Whether upon

For tooth loss, especially after multiple or complete tooth loss, removable dentures have become a vital method for restoring chewing

From birth to the emergence of the first baby tooth, individuals face the risk of tooth decay, one of the