Get Rid of Bad Breath

Bad breath, though not common in daily life, has been classified as a medical condition by the WHO. Whether upon

Prices You Can Trust

Turnaround Time

Skilled Technicians

PFM crowns with a lingual metal design reduce the amount of enamel removed from that area, increasing the tooth’s resistance. This design also lowers the chance of porcelain chipping during biting, significantly extending the crown’s lifespan. To maintain aesthetics, ISTAR limits the metal coverage to three-quarters of the tongue side, keeping it hidden while speaking or chewing.

The lingual metal material typically matches the inner metal material of porcelain-fused-to-metal crowns. You can let ISTAR know your specific needs:

Istar uses a shade guide to accurately match the patient’s natural tooth color, ensuring each PFM crown blends seamlessly with their real teeth. Our technicians hand-glaze the crowns and use precise temperature control in the porcelain furnace to enhance translucency, create a realistic shine, and achieve natural-looking layers for the best aesthetic results.

After receiving your case, our customer service team will translate your requirements into detailed instructions for our technicians to process:

Istar is a modern digital dental lab dedicated to providing high-quality dental products. We focus on using advanced smart equipment like 3D scanners, 3D printers, porcelain furnaces, and milling machines. These tools play a key role in our production process, greatly improving the accuracy, efficiency, and consistency of our dental work, ensuring higher satisfaction for you.

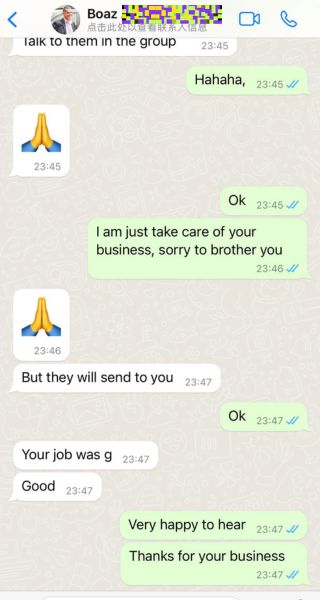

Istar has a professional customer service team with members who not only have strong English communication skills but are also very familiar with the dental prosthetic manufacturing process and technical details. We assign a dedicated “case manager” to each dentist, offering one-on-one service from design discussions to production updates, shipping arrangements, and after-sales support. This ensures smooth coordination at every step, efficiently fulfilling your order requirements and making your experience easier and hassle-free.

Istar has reduced the rework rate of PFM crowns to the lowest in the industry. This is thanks to our standardized processes and high-precision digital equipment, which ensure every porcelain crown meets quality standards. We also have an experienced quality control team, with each member having over three months of experience in various production stages. They are familiar with every detail and strictly oversee each step to ensure high-quality product delivery.

Bad breath, though not common in daily life, has been classified as a medical condition by the WHO. Whether upon

For tooth loss, especially after multiple or complete tooth loss, removable dentures have become a vital method for restoring chewing

From birth to the emergence of the first baby tooth, individuals face the risk of tooth decay, one of the